Your cast iron pipes can last up to a century, but you will still experience problems along the way. From corrosion to root damage to leaks, cast iron pipes require regular inspections and maintenance to function at top capacity. Understanding what to look for can help save you a lot of cash and even more hassle.

Table of Contents

- Overview of Cast Iron Sewer Pipe Challenges

- Signs of Cast Iron Sewer Pipe Failure

- Risks and Consequences

- Common Problems with Cast Iron Plumbing

- Why Cast Iron Pipe Inspections are Crucial for Your Property

- When to Repair or Replace Your Cast Iron Drain/Sewer Pipes

- Advantages of Modern Solutions

- Environmental Impact

- FAQs

Overview of Cast Iron Sewer Pipe Challenges

Cast iron sewer pipes used to be the standard installation choice for residences, though they’ve been largely replaced by either PVC or ABS pipes today. This swap occurred mainly due to the pipes’ heft and tendency to corrode and clog. A cast iron drain pipe can also damage the environment or the surrounding infrastructure. The impact of cast iron sewer pipes for property owners will depend on an array of factors. For instance, corrosion is particularly problematic if the pipes are in soil that’s more clay than sand. Plus, any exposure to extreme temperatures can result in the expansion of the pipes, and even prolonged exposure to hot temperatures can cause them to crack. The older the cast iron is, the more likely you will see these issues.

Cast iron plumbing is not necessarily bad news for a property owner. In other words, just because it has its challenges doesn’t mean you should replace all cast iron sewer plumbing. Cast iron is one of the most durable materials you can purchase, and a variety of older systems have operated without significant hiccups along the way. If you have cast iron pipes, the key to maintaining them is to get them inspected regularly and to keep up with your service schedule. When it comes to the longevity of your plumbing system, having the right team can make all the difference.

Signs of Cast Iron Sewer Pipe Failure

Cast iron pipes can last anywhere from a half-century to a century. As they age, you’re likely to see the following if they begin to fail:

- Odors: Sewer gas usually smells like rotting eggs, thanks to its combo of carbon dioxide, hydrogen sulfide, and methane. If no amount of cleaning will rid your drains of the smell, it’s likely coming from a damaged pipe.

- Clogs: Cast iron pipes can collect solids, whether grease or mineral deposits, over time. The more this material accumulates, the narrower your pipes will be and the slower the water will drain.

- Blockages: Total blockages can happen if clogs aren’t taken care of, but they can also occur if there’s a crack in the pipe. If there is a blockage, it will cause sewage to flow back up.

- Leaks: Any water damage, wet spots, or unexplained pooling can indicate that your cast iron pipes are leaking. Check the walls, ceiling, and floor for discoloration, mildew, mold, or dampness. It’s worth noting that plenty of older homes have cast iron pipes in areas that may not be used very often (e.g., basement corners). That’s why it’s important to check everywhere to assess the health of your pipes and drainage.

- Changes in the yard: If your cast iron pipes are intact until they reach your yard, you’re likely to see puddles of water. The more saturated your soil, the higher your odds of a sinkhole.

- Pests: Rodents and insects will flock to sewer gas. If you notice an infestation on your property, it could be due to sewer pipe failure.

Risks and Consequences Tied to Cast Iron Pipes

If you neglect cast iron sewer pipe issues, you must deal with the effects of raw sewage and water damage[1]. Sewage is home to bacteria, parasites, and viruses of nearly every variety. If you or your family have been exposed, symptoms can include headaches, nausea, fever, diarrhea, and weakness. Water damage that goes unaddressed can eventually lead to mildew or mold. It can damage the walls, tiles, and even fixtures.

Cast iron pipes have been a mainstay for homes, but they’ve been partially phased out due to their expense to repair. The longer the problems are unfixed, the more complex the repair process. In the worst-case scenario, you may even need to leave your home for a while. Homeowner’s policies may not always cover these types of repairs, depending on how the insurance company wrote the plan and how the damage occurred.

Common Problems with Cast Iron Plumbing

Cast iron plumbing is likely to see the following types of problems:

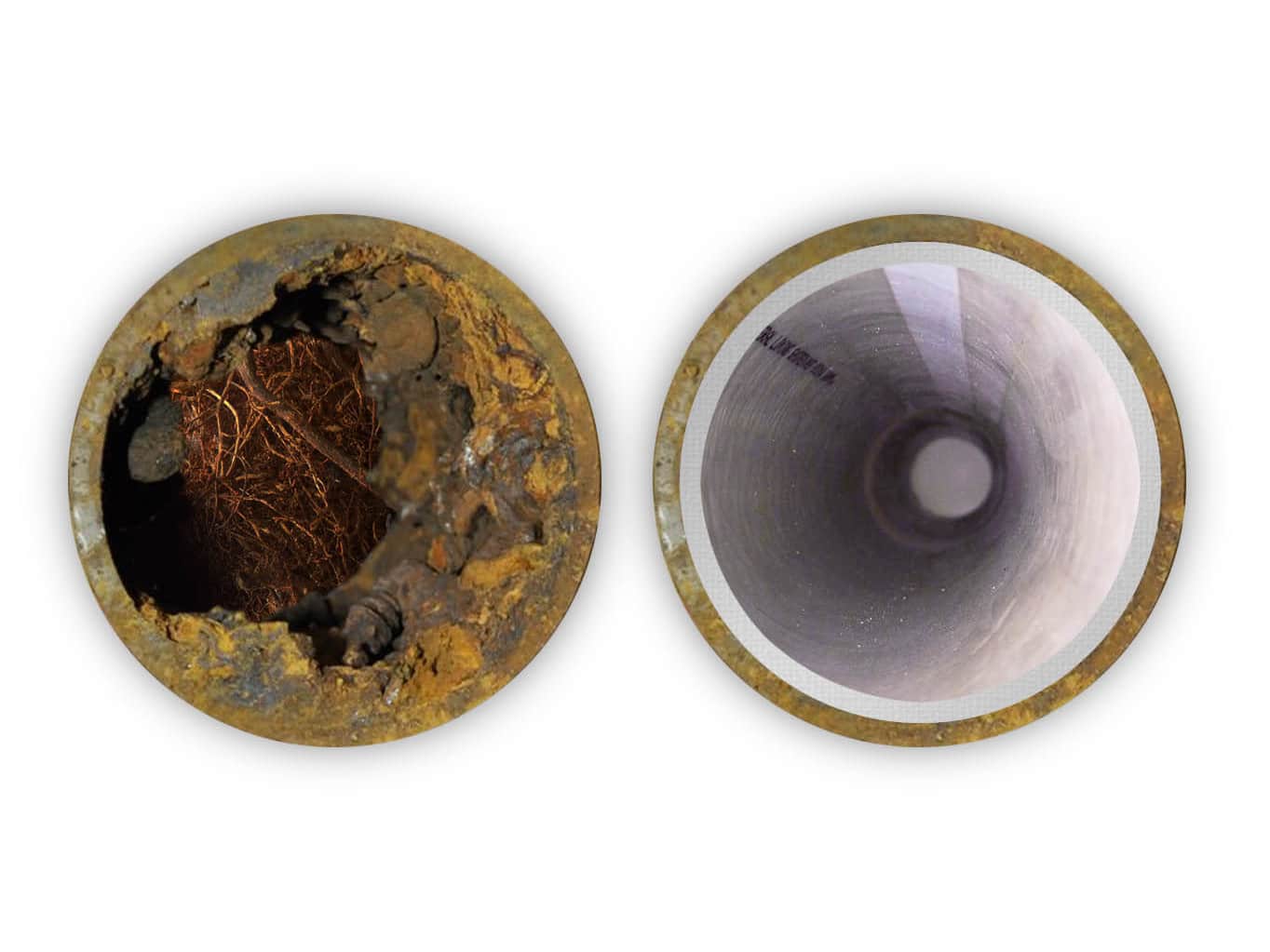

- Corrosion: Cast iron corrosion occurs with exposure to air and water[2]. Corrosion causes rust to build up and clog the pipes or eat through the pipes so the water and sewage gas can escape.

- Leaks: Leaks can be caused by corroding pipes, but they can also be due to root intrusion from surrounding trees, the shifting and settling of the ground, or the expansion of the pipes after they freeze and thaw.

- Blockages: The rust buildup from corrosion or debris can cause blockages. Trapped material can be anything from grease to paper towels to soap scum to hair. You can also have blockages if the pipes need to be correctly fitted and sloped or if the pipes work with a low-flow water system.

Cast iron pipe repair is not always as simple as patching a leak with epoxy. It can often take more serious investigatory skills to pinpoint what’s happening and how to best fix it.

Why Cast Iron Pipe Inspections are Crucial for Your Property

Cast iron pipe sewer inspections, look for more than just the standard problems any homeowner can spot. The right professionals will have the tools and expertise to examine your system on a micro-level, testing your water flow rate and checking the pressure to determine if leaks or damage still need to be apparent. Because an inspector knows what to look for, they can often catch what a standard homeowner inspection might miss. That said, it’s still important for owners to perform regular checks on a property for any signs of cast iron pipe damage.

Experts recommend having an inspection at least once every five years, even if your pipes are relatively new. If your system is older, you may need to have them inspected more often. Cast iron sewer pipe corrosion may take a while to manifest in bigger issues, but you never want to make assumptions about how long you have. A professional plumber can give you an idea of a more precise timeline for your property.

When to Repair or Replace Your Cast Iron Drain/Sewer Pipes

- It’s typically time to repair or replace your cast iron drains if they’re rusting, mislaid, disconnected, or damaged by tree roots[3]. A professional cast iron pipe plumber will survey the damage before making official recommendations. If the damage is relatively small, such as a small section of pipe just beginning to rust, the fix may be relatively minor and affordable.

Various factors, including the location of the pipes, impact the repair process. If the problem areas are easy to reach, a plumber may be able to get in and out quickly, which will typically make for a more affordable repair. If the pipe section is in a remote or otherwise inaccessible area, it will require more labor hours and expertise. The right plumber can help you avoid significant mishaps for more complicated repairs, particularly if you have a larger property to service. Generally, cast iron pipe repairs will be more affordable than replacements.

Advantages of Modern Solutions

Modern solutions for cast iron pipes are designed to offer property owners more convenience.

- Trenchless: An epoxy lining can protect cast iron pipes with a hard, smooth inner lining. A technician can place the lining without digging up your yard, which can go a long way to prevent rust and leaks.

- Versatile: Solutions such as a cured-in-place pipe (CIPP) lining are also trenchless options for pipes that need repair, but they’re more versatile than standard epoxy. It’s an excellent way to line nearly impossible-to-reach pipes.

- Innovative: Plumbers can use pipe bursting to break up sections of old pipes. Once this has been done, the tool installs a new pipe simultaneously. This incredible tool uses high-density polyethylene to fill the space left behind.

The Environmental Impact of Cast Iron Sewer Pipes

Cast iron has been phased out for various reasons, including the environmental impact of the material. Cast iron pipes require ore, coal, and limestone, which has led to soil degradation, water pollution, and greenhouse gasses.

When they leak, they deplete local water services and put more pressure on treatment facilities. Broken or misconfigured cast iron pipes can also cause the soil to become contaminated, and trace amounts of lead or arsenic from the pipes can eventually leak into the water supply. Plus, once they’re at the end of their lifestyle, they’ll continue contaminating water and soil if they’re not disposed of properly.

Cast Iron Pipe FAQs

Cast iron pipes can last for anywhere between 50 to 100 years. These durable materials are still used in various locations all over the US. The lifespan of these pipes varies based on everything from upkeep to the type of soil the cast iron pipes are exposed to, as clay will tend to corrode pipes faster than sand.

Yes, choose schedule 40 PVC for a durable replacement of traditional cast iron pipes, boasting a remarkable 50+ year lifespan. Alternatives like copper, CPVC, HDPE, polybutylene, and PEX pipes are also available based on your location and water usage needs.

Extreme cold will cause cast iron pipes to expand, leading to cracks in the pipes. Extreme heat, whether caused by the air or the water flow, can also cause the pipes to expand and contract. The latter is less common, but it can cause leaks.